Finding root-causes with Ishikawa – MES014

In the first session about root-cause analysis we have introduced the 5-Whys technique. It has its benefits, but also some severe disadvantages. As one of the most obvious ones the limitation on one root-cause can be highlighted.

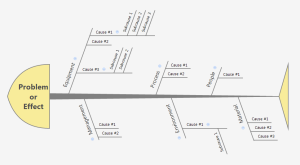

In this episode the Ishikawa technique will be introduced. The Ishikawa-diagram could be assumed as the big brother of the small 5-Whys. The Ishikawa covers all the limitations of the 5-Whys and provides a great way to also handle multiple root-causes and more complicated effects. But it also has its disadvantages and pitfalls.

Root-causes and the Ishikawa technique

The Ishikawa-technique is a graphical approach combining both, Brainstorming and Mind-Mapping. It is a valuable technique for group sessions. You will be astonished how progressive and fast you achieve results using the Ishikawa-approach.

If you need to dig deeper in your root-cause finding, then you will sooner or later be confronted with Ishikawa. Take this episode as your personal guidance to get an instant understanding how the technique is done. Moreover take my experiences with Ishikawa to circumvent usual problems and overcome common obstacles.

Essential Know-How Provided In This Episode:

- What helpful tools can be used to create an Ishikawa-diagram?

- Are there templates for the Ishikawa?

- When should Ishikawa be used preferrably?

- Which predefined categories of causes could you use in your Ishikawa?

- What’s the difference between sufficient and necessary?

- How mind-mapping can assist you with Ishikawa?

- And much much more

Possible categories of causes

- Traditional: Man, Machine, Milieu, Material, Method, Measurement

- 4 P’s of Marketing: Product, Place, Price, Promotion

- 7 P’s of Marketing: Product, Place, Price, Promotion, People/Personel, Process, Physical Evidence

- 5 M’s of Manufacturing: Machine (technology), Method (process), Material (includes Raw Material, Consumables, but also Information)

- 5 S’s in Services: Surroundings, Suppliers, Systems, Skills, Safety

- 7 S’s of McKinsey: Strategy, Structure, Systems, Share Values, Skills, Style, Staff

- My favorite: Measurement (inspection), Milieu (environment), Equipment, Material (Information), Methods (Processes), People, Management

Selected Links and Resources From This Episode

- Cause and Effect Fishbone Diagram

- Work visually, agile and boost your creativity and project with Stattys

I am a wholehearted SW-engineer on my journey to create a business supporting newcomers, seniors, managers and leaders.

I am a wholehearted SW-engineer on my journey to create a business supporting newcomers, seniors, managers and leaders.

Leave a Reply

Want to join the discussion?Feel free to contribute!